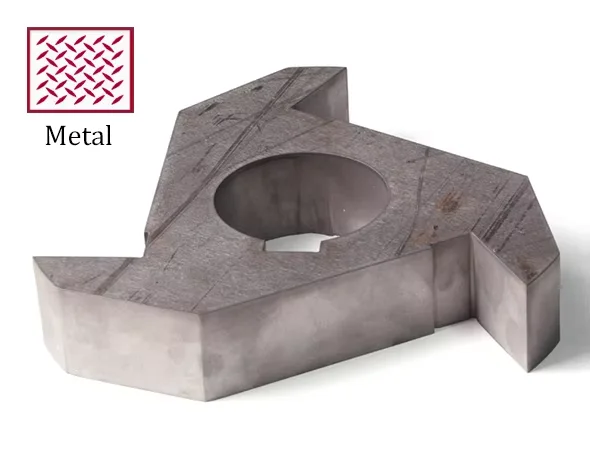

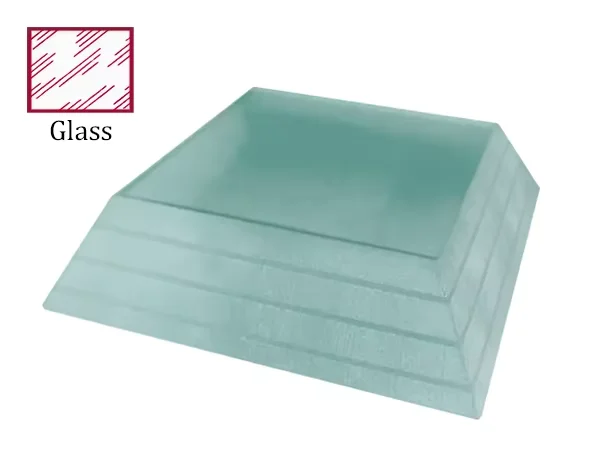

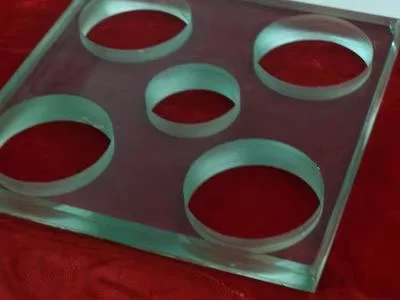

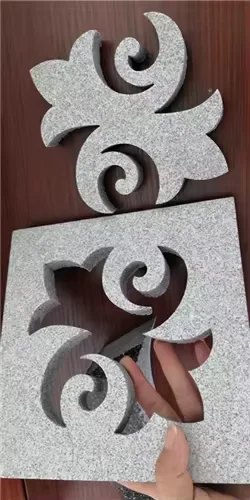

GoodCut GC4020WJ-5A 5axis Water Jet Cutting Machine for Stone Marble Metal Glass Bevel Cut with Heavy Machine Body

GoodCut GC4020WJ-5A 5axis Water Jet Cutting Machine for Stone Marble Metal Glass Bevel Cut with Heavy Machine Body

Technical characteristics description

CNC water-jet cutting machine is composed with cutting table, HP pump, CNC control system with waterjet cutting software, cutting head, Hp water valve, and sand controlling system . Auto abrasive feeding system and water cooling system are needed. Also you can choose optional systems such as water softening system and auto sludge removal system according your requests.

1. Cutting table

1.1 Platform body

1.1.1Chief technical parameter

Model | GC4020WJ-5A |

Structure | Split Gantry Type |

X axis | 4000mm |

Y axis | 2000mm |

Z-axis | 300mm |

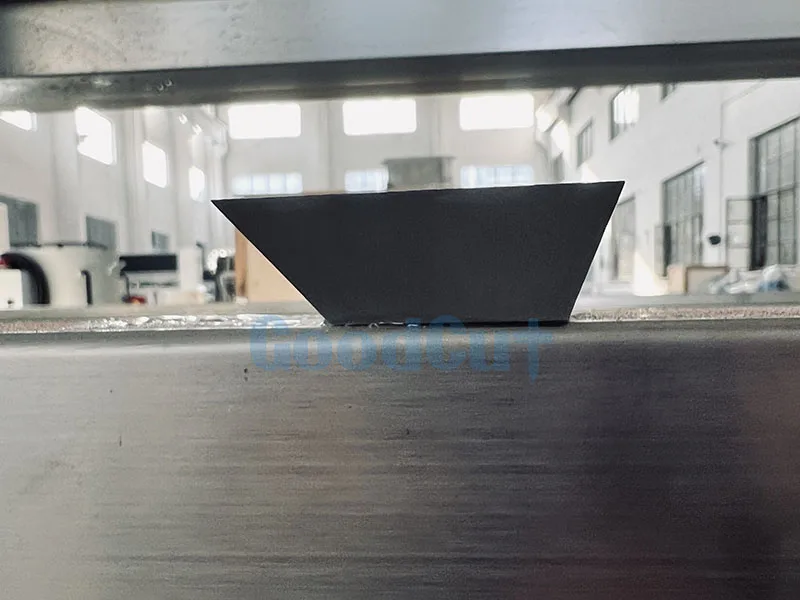

A-axis | ±75° |

C-axis | ±720° |

Effective cutting area | 4000×2000mm(bevel 45 degree) |

Control accuracy | ±0.01mm |

Repeatability accuracy | 0.02mm |

Running Speed | 15m/min |

Power | 380VAC, 50Hz , 3 phase 4 wire system(can be customized) |

1.1.2 Structure feature

- The machine body with the welding box structure, then make stress relief by annealing process.

- Table body and water tank which are split structure, lessen the splash of sands and water into moving parts, It is also conducive to the disassembly and transportation of the machine.

- X-axis and Y-axis transmit to rolling ball screw mandrel.

1.1.3 Controlling system

We adopt the WEIHONG controlling system based on the ADVANTECH industry computer,

YASKAWA digit servo driver and motor.

1.1.4Transmission system

- We adopt HIWIN linear guide rail and TBI ball screw to ensure accuracy and quality.

1.1.5Prevention system

- Over travel auto spacing function and soft spacing function

- Unique prevention design: new mazy protection and z-axis totally enclosed professional design prevent sand and water from eroding the guide screw and linear guide rail.

1.1.6Lubrication system

- We adopt auto mass lubrication system to make oil reach every oil site on time and also make table steadier and easier.

1.2 Cutting head assembly

1. 1.2.1 GC hp water switch

- Air valve can open and close the hp water instantaneously.

- With the help of CNC we can control hp water automatically.

- Blockage pressure can be adjusted arbitrarily to realize

the operation under the low pressure circumstances.

1.2.2 GC abrasive feeding system

- Dynamic sand feeding

- Manual makes up the sand for the feeder

(assisted with sand meter, auto feeder

can realize automatically feeding)

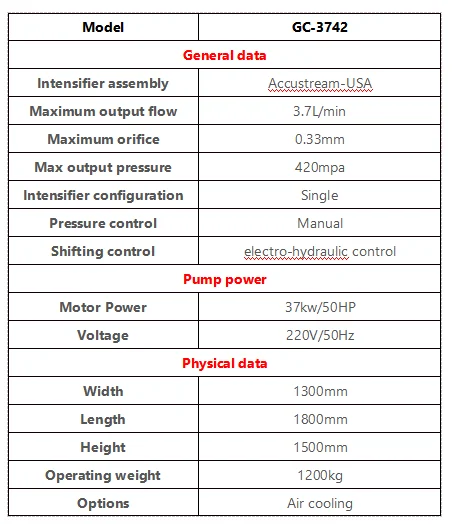

2. High Pressure Pump

Model:GC-3742

2.1 Chief technical parameter

2.2 HP Generator

-the configurations single pole two-way plunger type intensifier

- The main parts of intensifier assembly is imported the USA

(Accustream/Hypertherm)

- Single-row type water filtering system

(5Micron, 1micron, 0.45micronparallel)

- Manual pressure regulation function

- Extra pressure auto stop and protection

- Three-ply safeguards

3. CNC Controlling System & Software

3.1 CNC Controller

- 17”LCD touch screen display

- DNC on-line working function

- Functions of returning arbitrary point, bending,

and circular arc working auto deceleration.

- Function of cutting figure imitation display.

- 80GB memory hard disk

- MITSUBISHI AC servo driver and motor.

-1GB memory card

- Multilingual function(Chinese English ,etc.,)

- Drive-by-wire and hand-hold controller,(according to requests)

3.2 Software-NcStudio

NcStudio PCIMC-6A special software is special for GC.

The functions of PCIMC-6A are as follows:

- Change DXF document which is educed from AUTOCAD

into numerical control process.

- Serial communications between PC and CNC.

- Open database can shore parameter, just click the material,

prameter will be loaded automatically

- Calculate length of line and time automatically

- Control cut-out and cut-in automatically

- cutting track auto imitation function

- The functions of lessening speed on the corner remanding material bridging and lancing

3.3 3D Programming & Nesting-IGE

Modules | Remarks |

CAD-system | Includes basic 2X drawing commands such as line, circle, rectangle, copy, cut etc. Very user-friendly for operation. You can generate the geometry in the CAD-system. Note: it is one of the basic and necessary modules that support IGEMS. |

CAM tools | Includes commands for analyzing, preparing and optimizing the geometry before starting to make a toolpath. Note: it is one of the basic and necessary modules that support IGEMS. |

3-Axis CAM | Includes all the tools required to setup the machine and material database, prepare CNC files for the cutting process, postprocessing, calculate cutting times and much more. Note: it is one of the basic and necessary modules that support 5X-waterjet. |

AWJ module | AWJ stands for Abrasive Water Jet. So it is necessary for the Abrasive Water Cutting machine. By this module you can adjust the abrasive flow, pressure, speed, drilling and etc. |

Nest level 1 | This module is used to SEMI-automatically place parts on a sheet of material and minimize the material waste. |

5-Axis CAM | This module provides tools to prepare cutting in a 5-axis cutting machine. Strategies supported are cutting with fixed or various angles in flat material It supports the 3D file such as .STEP, IGS or STL file made in a 3D-system and add the toolpath in 3D |

4. Auto Abrasive Feeding System

4.1 DCAS-B abrasive meter regulator

- Side-hanging sand hopper

- There is a window on the side face. It can remind workers when to feed sand

- It can provide the sand consumption every time after it is filled up.

4.2 Abrasive hopper

- Dynamic sand feeding

- Dynamic type comes over traditional type.

- Manual type makes the operation easier.

- With the help of CNC we can control abrasive automatically

4.3 Abrasive Tank

- It provides the functions of shoring and sanding sands for the machine,

also improves the automation and lessens intensity of labor.

- Capacity: 170L

- High accuracy can remain workers when to feed sands.

5. Auto Cooling System

5.1 Auto Air Cooling system

- The working environment is clean and tidy.

- Good control the hydraulic system oil temperature.

5.2 Oil chiller

Model:GC250PAX

It can be set to any temperature, and is not subject to the working environment.

Refrigerating capacity:25000 Kcal/h

Voltage:380V 50Hz 3 Phase

Total unit capacity: 10.8KW

Water pump flow80L/min

Water lift:25m

Water Capacity:165L

Chilled water pipe diameter: G1.25”

Dimension: 980×1020×1700mm

Weight: 350KG

6. Water Soften System

Here are many kinds of compounds in the running water.

(Calcium carbonate, carbonic acid)As the machine

working, the raising of the temperature will generate

some substance of the reaction of chemistry or physics-as

we called it furring, which will reduce the life of the high

pressure system and increase the cost. After many years’

experiences, the system can solve the problem.

7. Sludge Removal System

Introduction:

Remove the abrasive from the tank automatically,

separate the abrasive and water. reduce the labor force,

improve work efficiency.

Suction pump parameters:(China)

The single pump parameters

Flow: 10M³/H

Shoot range : 50 M

Outlet pressure: 6 kgf/cm²

Absord range: 7 M

Maximum promise through solid part: 4.5mm

Pump inlet and outlet diameter: 40mm

Power:compressed air

The max inlet pressure: 7 kgf/cm²

The max air consume: 0.6 mm³/min

Tracheal diameter:10mm

Collection box: 1.6m*1.5m*1.2m

One set including pipe parts,total is two sets

One year warranty period (except for vulnera)

Payment term:

a. Payment terms and conditions:

1.Payment terms:30% payment by T/T in advance;the balance should be paid before delivery by T/T.

2.Trade terms: EXW

Within 40 days after receiving the deposit

Quotation details | |||||

No. | Name | Model | Specification | Qty | Unit price |

(USD) | |||||

1-2 | CNC waterjet machine Standard 5 axis | Cutting table: GC4020WJ-5A | Cutting area: 4.0×2.0M(45°bevel) | 1 | |

CNC controller | WEIHONG | ||||

3 | High pressure pump | GC-3742 | Maxi pressure: 420MPA | 1 | |

Tools & Spare parts | List 1&List 2 | Free with the machine | 1 | ||

4 | Abrasive feeding system | GC-A | 170Kg | 1 | |

5 | Air cooling system | GC-B |

| ||

6 | Wireless Hand wheel remote | GC-E | 1 | ||

No. | Photo | Name | Amount | |

一.Spare parts for the machine | ||||

1 | Ruby | 4 | ||

2 | Nozzle | 1 | ||

3 | Connecter of pipe(each one for larger and samller) | 2 | ||

4 | The shift valve elements | 1 | ||

5 | The air valve repair kit | 1 | ||

6 | Shield cap | 2 | ||

7 | Hp water switch kit | 1 | ||

8 | Hp seal(without copper cake ) | 1 | ||

9 | Low pressure oil seal | 1 | ||

10 | Lp check valve repair kit | 1 | ||

11 | filter element(5Micron) | 1 | ||

12 | filter element(1Micron) | 1 | ||

13 | Fold filter(0.45Micron) | 1 | ||

14 | The Blue Lubricant | 1 | ||

15 |

| O ring and assembled ferrule | 1 | |

二.Special tools for machine | ||||

1 | 60K Intensifier Tool kit (For H-P Seal) | 1 | ||

2 |

| Wrench Girth (For H-P Cylinder) | 1 | |

3 |

| Wrench,Spanner(For End Cap) | 1 | |

4 | Wrench,Spanner(For HIGH PRESSURE SWITCH) | 1 | ||

No. | Name | manufacturing company | country |

Controlling System | |||

1 | Control Card | WEIHONG | China |

Software | |||

2 | Programming & Nesting software | IGEMS | Sweden |

3 | Industry Computer | ADVANTECH | Taiwan, China |

4 | AC servo driver | YASKAWA | Japan |

AC servo motor | |||

Cutting Table | |||

1 | Cutting head assembly | GOODCUT WATERJET | China |

On/Off repair kit (cutting head) | Accustream | ||

2 | Ball screw | TBI | Taiwan, China |

Linear guide rail | HIWIN | ||

3 | Platform | GOODCUT WATERJET | China |

High Pressure Pump | |||

1 | High pressure pump | GOODCUTWATERJET | China |

2 | Intensifier assembly | Accustream | USA |

3 | Electric appliance | SCHNEIDER | France |

4 | PLC | Siemens | Germany |

main motor of HP pump | |||

Equipment installation conditions

Power requirements:

- 380VAC, 50Hz ,3 phase

- 100A

Air Pressure Request:

- Compressed air supply pressure:>6KG/cm2

- Compressed air supply:>0.3m3/min

Water Request:

- Cutting water inlet pressure: 2-4 kg/cm2

- Minimum water supply for cutting water: 8l/min

- Cooling water pressure: 2-7kg/cm2

- Cooling water consumption: 10-20l/min

Hydraulic oil:

- 46#anti wear hydraulic oil :200Kg

Installation and Debugging:

The assembling of the machine

In accordance with the requirements of the equipment installation instructions provided by GC waterjet, the user will be required to prepare and confirm the installation conditions, will send engineer to guide the trianer to assemble and debug the machine

- Users in accordance with the requirements of the installation of the equipment provided by the company in GC watejet to carry out construction.

- The user is responsible for the equipment in the factory unloading and unpacking, and equipment in place

- The user is responsible for providing the installation and debugging process of the necessary lifting equipment and general tools (such as wire rope, soft sling, wrench, screwdriver, universal meter, etc.)

- The user is responsible for the equipment to install the necessary materials, such as hydraulic oil, machine tool external power supply cable, water pipe, etc.

- User is responsible for the power, water, gas source, drainage pipe and other transfers to the workstation

- The user is responsible for the appointment of technical personnel to the site with the GC waterjet engineers for equipment installation

- Installation and commissioning of all equipment within 10 working days after user notification

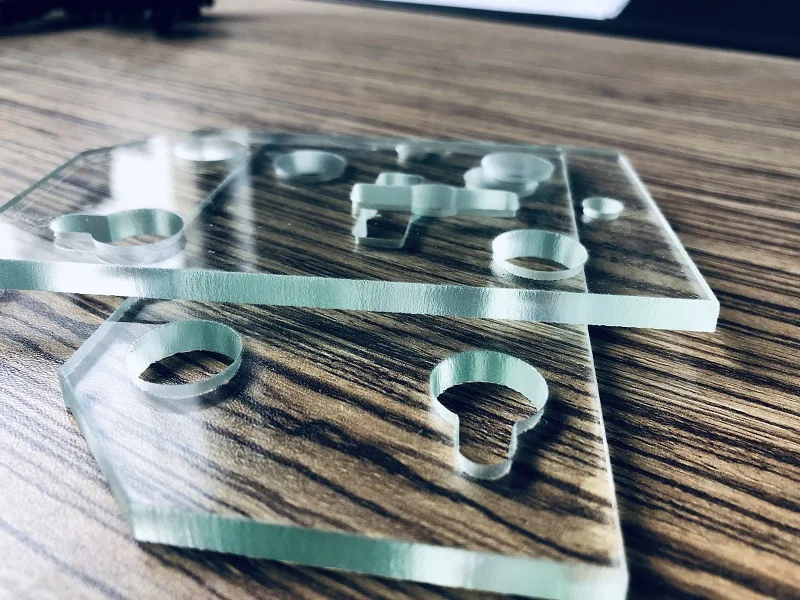

Materials: Stone, metal ,glass.